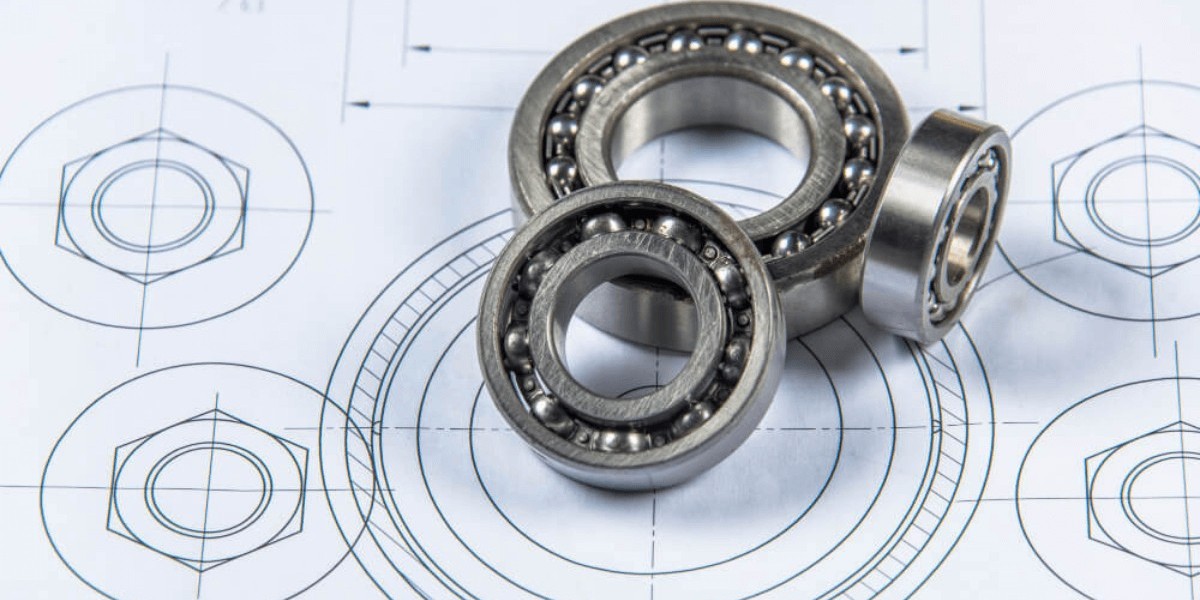

Industrial machinery breakdowns can disrupt production and lead to expensive repairs. Often, the root cause is overlooked: the bearings. Low-quality or worn-out bearings can cause machines to overheat, vibrate, or stop unexpectedly. The vkjp84887 mechanical roller ball bearing is engineered to handle heavy loads and maintain smooth operation, but neglecting maintenance can result in serious problems.

In this article, I will explain why choosing the right vkjp84887 bearing is critical, how to identify early warning signs, and tips to maximize its performance.

Why VKJP84887 Bearings Are Essential

The vkjp84887 is a precision roller ball bearing designed for high-load applications. Its main functions include:

Reducing friction – Smooth rotation ensures less wear on connected components.

Supporting heavy loads – Handles both radial and axial pressures efficiently.

Increasing durability – Made with high-quality materials to resist heat, corrosion, and deformation.

Using the proper vkjp84887 bearing helps prevent unplanned downtime and extends the lifespan of machinery.

Signs Your Bearing Needs Attention

Detecting bearing issues early can save significant costs. Common warning signs include:

Excessive noise or vibration – Grinding, clicking, or humming noises often indicate wear or misalignment.

Overheating – Can result from insufficient lubrication, overload, or friction.

Visible damage – Cracks, corrosion, or worn surfaces reduce efficiency.

Frequent malfunctions – Machines needing constant repairs may indicate the wrong or low-quality bearing is used.

Replacing or upgrading to a high-quality vkjp84887 bearing at the right time ensures smooth and safe operation.

Tips for Maximizing VKJP84887 Performance

Correct installation – Improper fitting reduces bearing life and efficiency.

Regular lubrication – Use the manufacturer-recommended grease or oil to minimize friction.

Monitor operating conditions – Avoid overloading, misalignment, or extreme temperatures.

Routine inspections – Check for wear, noise, or overheating to catch problems early.

Proper maintenance helps extend the life of your vkjp84887 bearing and keeps machinery running reliably.

Advantages of Choosing the Right Bearing

Using a high-quality vkjp84887 bearing offers several benefits:

Reduces downtime – Keeps your production line running without interruptions.

Lowers maintenance costs – Fewer replacements and emergency repairs.

Boosts efficiency – Smooth rotation improves machine performance.

Enhances safety – Reduces risk of mechanical failures or accidents.

Investing in the correct bearing protects your machinery, reduces costs, and ensures reliable operations.

Conclusion

Machine failures caused by bearing issues can be costly and disruptive. Selecting and maintaining the proper vkjp84887 mechanical roller ball bearing is essential for smooth, efficient, and safe operation. Regular inspections, proper installation, and timely lubrication can significantly extend bearing life, prevent unplanned downtime, and save money. Don’t risk your machinery’s performance—upgrade to the reliable vkjp84887 bearing today.