In the world of modern manufacturing, precision and efficiency are more important than ever. Industries that deal with metal fabrication face constant pressure to deliver high-quality products while minimizing waste and operational costs. This is where laser machine metal cutting comes into play, transforming the way businesses approach metalworking. At Mart Laser, we bring state-of-the-art laser cutting technology that caters to diverse industrial needs.

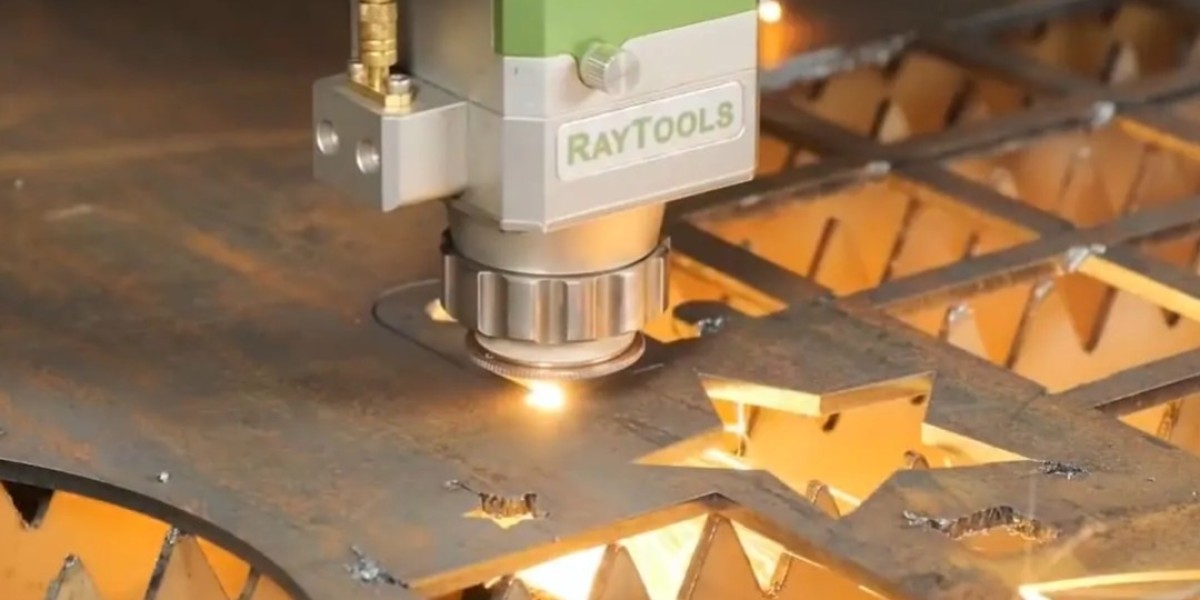

Laser machine metal cutting offers a level of accuracy that traditional cutting methods often struggle to achieve. Whether it is stainless steel, aluminum, or other metals, laser machines can cut complex shapes and patterns with minimal material loss. Unlike conventional cutting methods, which may require multiple steps and tools, laser cutting streamlines the process, saving both time and labor costs. Mart Laser ensures that every machine we provide is optimized for consistent performance, making high-precision projects manageable and reliable.

Another significant advantage of laser machine metal cutting is its adaptability. Industries ranging from automotive and aerospace to construction and art design require precise metalwork for custom components, structural parts, or decorative elements. Mart Laser’s machines are engineered to handle a wide variety of materials and thicknesses, providing flexibility for businesses to expand their production capabilities. With cutting-edge software integration, our machines offer programmable control that allows operators to execute complex designs effortlessly, maintaining accuracy across repeated operations.

Safety and ease of use are also key priorities for Mart Laser. Our laser machines come with advanced safety features, ensuring operators can work confidently without risk of accidents. User-friendly interfaces and automated processes reduce the learning curve, making it easier for teams to adopt laser cutting technology even if they are new to high-tech metal fabrication. This combination of safety, precision, and efficiency makes Mart Laser the preferred choice for businesses looking to upgrade their manufacturing workflow.

Investing in a laser machine metal cutting system from Mart Laser is not just a step toward improved production; it is an investment in innovation. By integrating laser technology into your operations, you enhance not only the quality of your products but also your overall business competitiveness. Faster production times, minimal errors, and the ability to produce intricate designs allow businesses to take on more ambitious projects and satisfy customer demands more effectively.

Mart Laser is committed to supporting its clients with exceptional customer service and technical guidance. From selecting the right machine for specific requirements to maintenance and training, our team ensures that each client receives full support to maximize the benefits of laser machine metal cutting.

In conclusion, laser machine metal cutting represents a transformative approach to metal fabrication, combining precision, efficiency, and flexibility. With Mart Laser, businesses gain access to cutting-edge technology that streamlines operations, enhances product quality, and opens new possibilities for creative and industrial applications. For companies looking to modernize their metal cutting processes, Mart Laser stands as a reliable partner in achieving excellence.