Introduction

Your loader breaks down on a Tuesday morning. The hydraulic pump failed. The repair costs $4,800. Your crew sits idle for three days. The project falls behind schedule. Your client gets angry.

Here's the worst part: this breakdown was completely preventable. The maintenance manual said to service the hydraulic system every 500 hours. Your loader hit 847 hours since the last service. You just didn't know.

Nobody tracked it. Nobody reminded you. The information lived in a binder somewhere, and the hours quietly ticked up until the pump gave out.

This scenario repeats itself thousands of times daily across every industry. Equipment breaks down not because it's old or poorly made, but because nobody performed routine maintenance on time.

Preventive maintenance works. Studies show it reduces breakdowns by 70% and extends equipment life by 20-30%. But only if you actually do it. And doing it requires tracking intervals, scheduling services, ordering parts, and coordinating technicians.

Equipment cost software transforms preventive maintenance from a chaotic afterthought into an automated system that actually prevents failures. Let's explore exactly how these tools manage maintenance so your equipment stops breaking at the worst possible moments.

The Preventive Maintenance Problem

Most businesses know they should do preventive maintenance. Few actually execute it consistently.

Nobody Knows When Maintenance Is Due

Your excavator needs an oil change every 250 hours. Your forklift needs one every 500 hours. Your concrete mixer follows calendar intervals—service every three months regardless of usage.

Without a tracking system, you're relying on operators to remember or managers to somehow know when each machine crosses its service threshold. This doesn't work. Things get missed. Equipment runs past maintenance windows. Failures follow.

Maintenance Information Lives Everywhere

The maintenance manual lives in a filing cabinet. Hour meter readings exist in operator logbooks. Service records are in a different binder. Last service dates are in someone's head or scattered across invoices.

When maintenance information lives everywhere, it effectively lives nowhere. You can't make decisions with data you can't access.

Parts Aren't Available When Needed

You finally schedule maintenance, then discover you don't have the right oil filter in stock. The service gets delayed while you order parts. Meanwhile, the machine keeps running past its maintenance interval, increasing failure risk.

No Accountability

Who's responsible for ensuring maintenance happens? The operator? The maintenance supervisor? The fleet manager? When everyone's responsible, nobody's responsible. Maintenance reminders get ignored. Services get postponed because you're busy. Equipment keeps operating until something breaks.

How Equipment Cost Software Solves These Problems

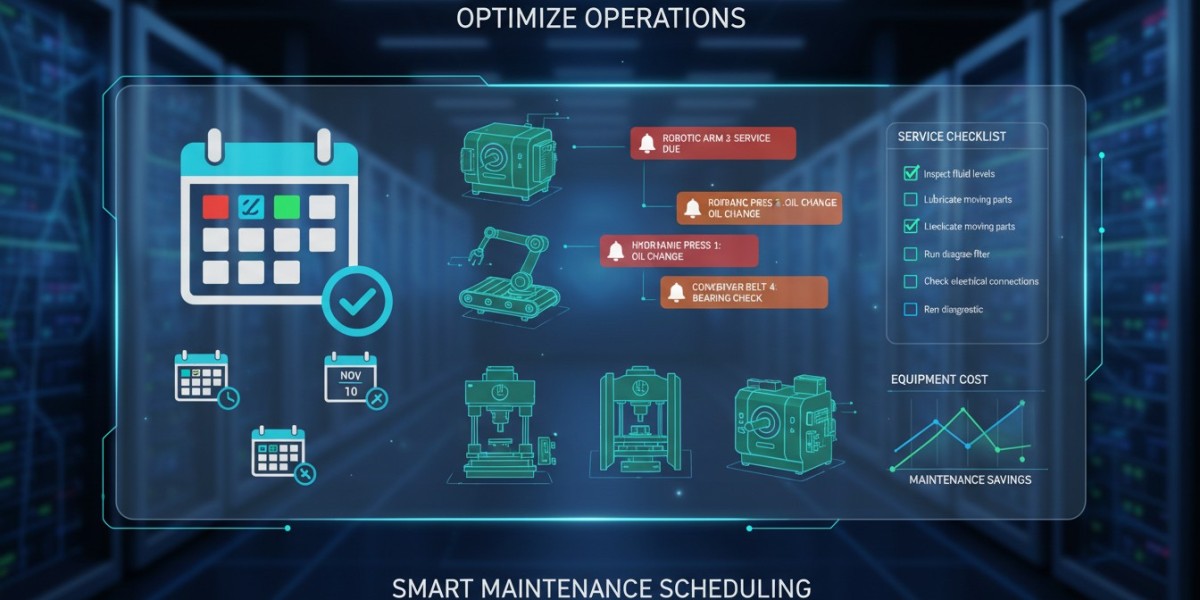

Modern equipment cost tools automate the entire preventive maintenance workflow from scheduling through completion.

Automatic Interval Tracking

When you add equipment to the system, you configure its maintenance schedule. Oil changes every 250 hours. Hydraulic fluid replacement every 1,000 hours. Annual inspections every 12 months. Belt inspections every 500 hours or six months, whichever comes first.

The software tracks multiple interval types simultaneously: operating hours, calendar time, miles driven, or production units. Your dump truck might need service every 10,000 miles or six months. The system monitors both and alerts based on whichever threshold hits first.

For equipment with telematics integration, the software pulls hour meter readings automatically. No manual data entry. The system knows exactly where each machine stands relative to its next service interval.

Smart Scheduling and Alerts

As equipment approaches maintenance intervals, the software generates alerts. You might receive notifications at 90%, 100%, and 110% of the maintenance interval. This gives you advance warning to schedule services during convenient downtime instead of being forced into emergency maintenance.

Alerts go to the right people. Operators get notified that their machine needs service soon. Maintenance supervisors see which equipment requires attention this week. Managers receive summaries showing fleet-wide maintenance status.

You can customize alert timing and recipients. Maybe you want a 30-day advance notice for annual inspections so you can schedule them during slow periods. The software handles this automatically.

Integrated Work Order Management

When maintenance is due, the software automatically generates work orders. These work orders include complete service details: what needs to be done, required parts, estimated labor hours, and recommended completion date.

Technicians receive work orders through mobile apps. They see exactly what service the equipment needs, access maintenance procedures digitally, and log completed work directly from their phones.

No more paper work orders that get lost. No more verbal instructions that get misunderstood. Everything is documented, assigned, and tracked digitally.

Parts Inventory Integration

Smart equipment cost software connects to your parts inventory system. When a maintenance interval approaches, the system checks whether required parts are in stock.

Filter inventory is low? The software flags this weeks before the service is due, giving you time to order parts. Some systems can even generate purchase orders automatically based on upcoming maintenance requirements.

This integration eliminates last-minute parts shortages that delay maintenance.

Calendar-Based vs. Usage-Based Maintenance

Different equipment requires different maintenance strategies. Software handles both seamlessly.

Usage-Based Maintenance

Most mobile equipment follows usage-based schedules. Your excavator needs service every 250 hours whether that takes two months or six months.

Software with telematics integration tracks usage automatically. The system monitors actual operating hours in real-time, updating maintenance schedules continuously. You always know exactly when the next service is due.

This prevents over-maintenance too. If a machine only operates occasionally, you're not wasting money on unnecessary services just because the calendar says it's time.

Calendar-Based Maintenance

Some equipment needs maintenance on fixed schedules regardless of usage. Batteries need testing every six months even if the forklift barely runs. Refrigeration units require annual inspections by regulation.

The software tracks calendar intervals automatically, ensuring you never miss regulatory compliance deadlines or manufacturer-recommended services.

Combination Intervals

The most sophisticated approach uses both methods. Service equipment every 500 hours OR every six months, whichever comes first.

Software monitors both thresholds simultaneously and triggers maintenance based on whichever condition arrives first. You get optimal maintenance timing without manual oversight.

Maintenance History and Pattern Recognition

Tracking when maintenance is due is valuable. Understanding maintenance patterns is transformative.

Complete Service History

Equipment cost software maintains detailed records of every service event: what was done, when, by whom, at what hour meter reading, which parts were used, and what it cost.

You can pull up any machine and see its complete maintenance history instantly. This visibility helps diagnose recurring problems. Your loader has had three hydraulic hose replacements in eight months? That's not random—something's causing premature hose failure.

Without historical tracking, you'd replace hoses reactively without ever recognizing the pattern.

Predictive Maintenance Opportunities

Advanced software analyzes maintenance history to predict future issues. It notices that your 2019 excavators typically need track replacement around 3,200 hours. Your 2019 excavator currently shows 2,950 hours.

The system proactively alerts you that track replacement is likely within the next 250 hours. You can schedule this major service during planned downtime instead of dealing with track failure during a critical project.

Identifying Problem Equipment

Historical data reveals which machines consume excessive maintenance resources. Your fleet has eight forklifts. Seven average $1,200 annually in maintenance. One costs $4,800.

The software highlights this outlier automatically. Maybe it's a lemon that should be replaced. Maybe it operates in harsh conditions. Whatever the cause, you can't address problems you don't see.

Mobile Maintenance Management

Maintenance happens in the field, not at desks. Modern equipment cost tools provide mobile functionality that brings digital management to where work actually occurs.

Mobile Work Orders

Technicians receive work orders on smartphones or tablets. They see equipment details, service requirements, parts needed, and access digital maintenance manuals—all from their device.

When service is complete, they log it immediately. Record what was done, note any issues discovered, attach photos of problem areas, and mark the work order complete. This information syncs to the central system instantly.

Equipment QR Codes

Many businesses attach QR code labels to each piece of equipment. Technicians scan the code with their phone, instantly accessing that machine's complete profile: maintenance history, current service needs, parts inventory, and operator manuals.

This eliminates confusion about which machine needs service. Scan, verify, perform maintenance, log completion. Simple and error-proof.

Regulatory Compliance and Safety Inspections

Some maintenance isn't optional—it's legally required. Equipment cost software helps ensure you never miss mandatory inspections.

Compliance Tracking

The software tracks regulatory inspection requirements for each asset. Aerial lifts need annual inspections. Forklifts require daily operator checks. Commercial vehicles need DOT inspections.

These requirements get scheduled like any other maintenance, with alerts ensuring services happen before deadlines. The system generates compliance reports showing inspection dates, results, and certifications—exactly what auditors and inspectors want to see.

Safety Inspection Checklists

Daily operator inspection checklists can be digitized and managed through the software. Operators complete digital checklists before using equipment each day. Failed items generate automatic work orders for maintenance.

This creates accountability. Operators can't skip inspections because the system requires checklist completion before equipment operation.

Cost Tracking and Budget Management

Preventive maintenance has costs. But these costs are predictable and manageable compared to emergency breakdown expenses.

Preventive vs. Corrective Cost Analysis

Software separates preventive maintenance costs from corrective repair costs. You see exactly how much you're spending to prevent failures versus fixing things that break.

The ideal ratio is about 70% preventive, 30% corrective. If your numbers show 40% preventive and 60% corrective, you're being too reactive. This visibility drives behavioral change.

Maintenance Budget Forecasting

Because preventive maintenance follows predictable schedules, the software can forecast future costs with high accuracy. It knows what services are due over the next 12 months and estimates costs based on historical data.

Your budget planning improves dramatically. Instead of guessing at maintenance costs, you have data-driven projections showing month-by-month expenses.

The Bottom Line

Preventive maintenance is simple in theory: service equipment before it breaks. But execution requires tracking dozens of schedules across multiple machines, coordinating parts and technicians, documenting compliance, and managing costs.

Doing this manually is impossible at scale. Spreadsheets and paper logs can't handle the complexity. Things get missed. Equipment breaks down. Costs spiral out of control.

Equipment cost software automates the entire preventive maintenance workflow. It tracks intervals, generates alerts, creates work orders, manages parts inventory, documents compliance, and provides mobile tools for field execution.

The result? Maintenance actually happens on schedule. Breakdowns decrease by 70%. Equipment lasts 20-30% longer. Emergency repair costs plummet. Your operation becomes predictable instead of chaotic.

The businesses crushing it in your industry aren't lucky. They simply manage maintenance systematically using tools designed for the job.

You can keep fighting preventive maintenance chaos with spreadsheets and hope. Or you can automate the system and watch breakdown emergencies become rare exceptions instead of weekly disasters.

Your equipment will break eventually. The question is whether it breaks on your schedule or its own. For a more efficient way to schedule and manage preventive maintenance, check out Intersoft ERP now.