(HDPE) high-density polyethylene sheets have an extremely durable, chemical resistant makeup and use a minimum number of fillers. These are thermoplastic polymer sheets of incredible strength and flexibility, which makes them great for use in a myriad of projects. With changing industry trends and the need to adhere to higher industry standards for sustainable living, HDPE sheets rightfully remain one of the best raw materials available today with several unique characteristics that sell themselves in amazing prices because you have more and more HDPE sheet suppliers around the world.

Understanding the Composition and Properties of HDPE Sheets

HDPE sheets or polyethylene high-density (Plastic Sheet) is a Generally provide in 4 x 8 & 10-meter dimensions, available that comes form the highest quality Using linear structure and minimal branching of its molecules. It is this structure that makes HDPE so strong, with high tensile strength and good impact resistance which can withstand even the toughest of environments. One of the primary features of HDPE sheets is their excellent resistance to chemicals, such as acids, alkalis and alcohols. They are also moisture and UV resistant, meaning you get good mileage out of them even outdoors. These features make HDPE sheet manufacturer ideal for use in construction, agriculture, transportation and manufacturing industries.

The Role of HDPE Sheet Manufacturers

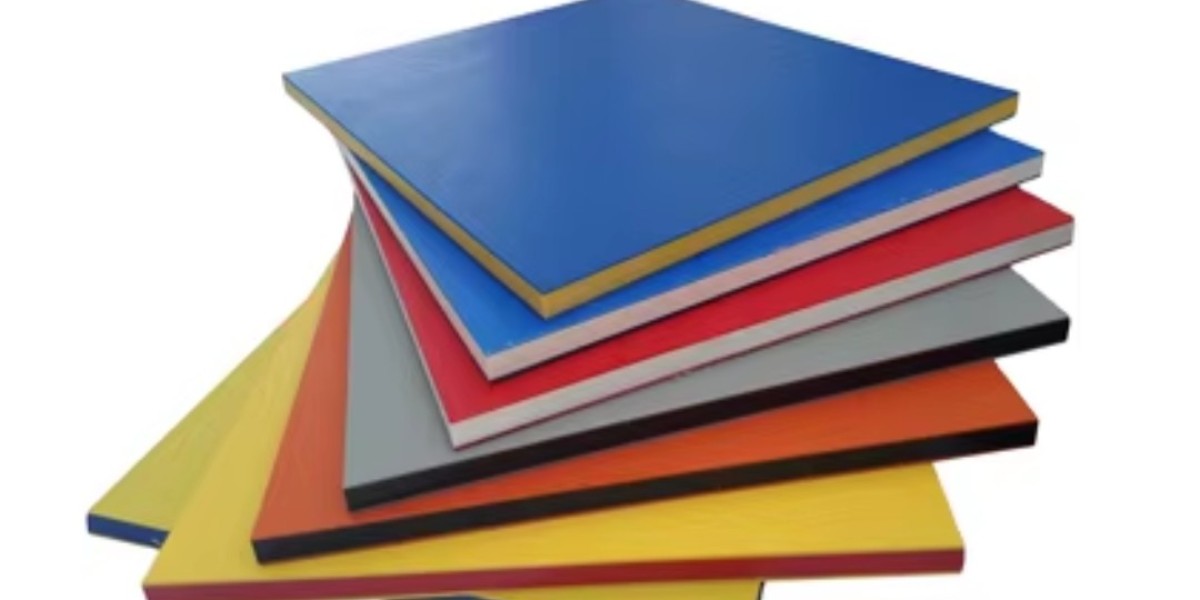

The world of HDPE sheets is largely dominated by manufacturers focused on quality, innovation and environmental sustainability. Top HDPE sheet manufacturers use high quality techniques such as extrusion, compression molding, and injection molding during the manufacturing process to guarantee that each of their products meets strict strength, flexibility, and chemical resistance standards. They're also increasingly specialized, addressing the specific needs and requirements of individual industries such as thickness variation, surface textures or range of colors. It is no wonder that several different HDPE sheet manufacturers exist within an already-extensive market -this competition can help keep prices competitive while spurring innovation and raising product quality at the same time.

Applications of HDPE Sheets in Various Industries

HDPE sheets are very versatileandarewidely used to a variety of end uses. Due to their strong and wear-resistant properties, they are also employed as protective inlays/wall-boarding/floor tiles/slabs within the building industry. In agriculture, they are used as lining for ponds, silos and irrigation ditches – resistant to rusting/contamination/degradation by non-neutral pH liquids. In the transportation segment, HDPE sheets are used for truck bed liners and containers that require impact resistance and weatherability. They are also a preferred option for the production of parts which call for machinability and weight. Within the food and drug industries, professionals count on HDPE for its clean, yet versatile properties - making the material itself an ideal cleaning solution that meets FDA standards.

Environmental Benefits and Sustainability of HDPE Sheets

Their relatively friendly environmental footprint is one of the reasons that leads to a growing demand for HDPE sheets. As an added benefit, HDPE is a recyclable material and there are many HDPE sheet manufacturer that play up their use of “eco-friendly” production methods. Recycling HDPE reduces the energy cost of producing new items and is a boon for businesses wishing to be more eco-friendly. Plus, HDPE sheets are long-wearing, so they don’t need to be replaced as often — and that means less work for the environment. They are impervious to virtually all weather extremes and will not require expensive maintenance or painting.

Choosing the Right HDPE Sheets for Your Needs

Choosing the right HDPE sheets is easy to do when you factor in thickness, surface finish, and color; then add optional accessories like cutting or drilling. Quality HDPE sheets are versatile and have many different applications, but specific uses depend on the particular requirements of your project.Whether you’re seeing to make a purchase order stock plastic otherwise you’re ready to switch to custom parts or a new stock shape, an excellent place to begin is discovering high-quality HDPE sheet manufacturers. So thicker sheets provide better impact resistance, while ones with texture offer improved traction in flooring applications. It is also crucial to verify the company’s manufacturing quality standards, mostly their ISO certifications (to ensure a reliable product). Consulting with manufacturers and suppliers may help determine which HDPE sheets are best suited to your application, in terms of performance, longevity and cost-effectiveness.

Conclusion

The demand for HDPE Plastic sheets will likely to grow as companies are looking for durable, recyclable and cheap material. Their unique combination of strength, resistance and sustainability mean they are ideal for a variety of applications. Do to the rapid growth of professional HDPE sheet manufacturers dedicated to innovation and quality, businesses are able to choose from many different types of solutions for their company specific needs. In the future, improvements in manufacturing and recycling methods are expected to further improve HDPE sheet efficiency and sustainability, keeping the material as a prominent option for decades.

Frequently Asked Questions

What are the main advantages of using HDPE sheets over other plastic materials?

HDPE panels have more impact and chemical resistance than others, but are also UV stable and fit in seamlessly with any environment; Anywhere a durable, alternative to wood or other materials is needed.How can I determine the right thickness of HDPE sheets for my application?

The right thickness of material varies based on the use — shock resistance might be more important for some, while load-bearing capacity is a consideration for others, as well as exposure to environmental conditions. Talking to manufacturers of HDPE sheet can determine what would serve best.Are HDPE sheets safe for food contact applications?

Quite a few suppliers even sell FDA-approved HDPE sheets that are okay for direct food contact, nontoxic when rinsed and easy to clean, which is ideal for the food processing and packaging industry.- Who is the largest supplier of HDPE Sheets?

Singhal Global PVT Ltd is one of the suppliers of HDPE sheets, but it is not necessarily the largest globally. What are the environmental benefits of using HDPE sheets?

This bike rack is made of durable, recycled HDPE which is recyclable itself and limits waste and a long product life for environmentally friendly working methods for the betterment of our planet.