At G&H Div, we are committed to helping oil and gas operators optimize their well performance with advanced tools and technologies. In today’s competitive energy industry, understanding and properly deploying equipment like the perforating gun, frac plug setting tool, and loaded perforating gun is essential for safe, efficient, and effective operations. In this article, we’ll break down these key tools, explain their benefits, and show how G&H Div supports operators with innovative solutions.

The Role of Perforating Guns in Well Completion

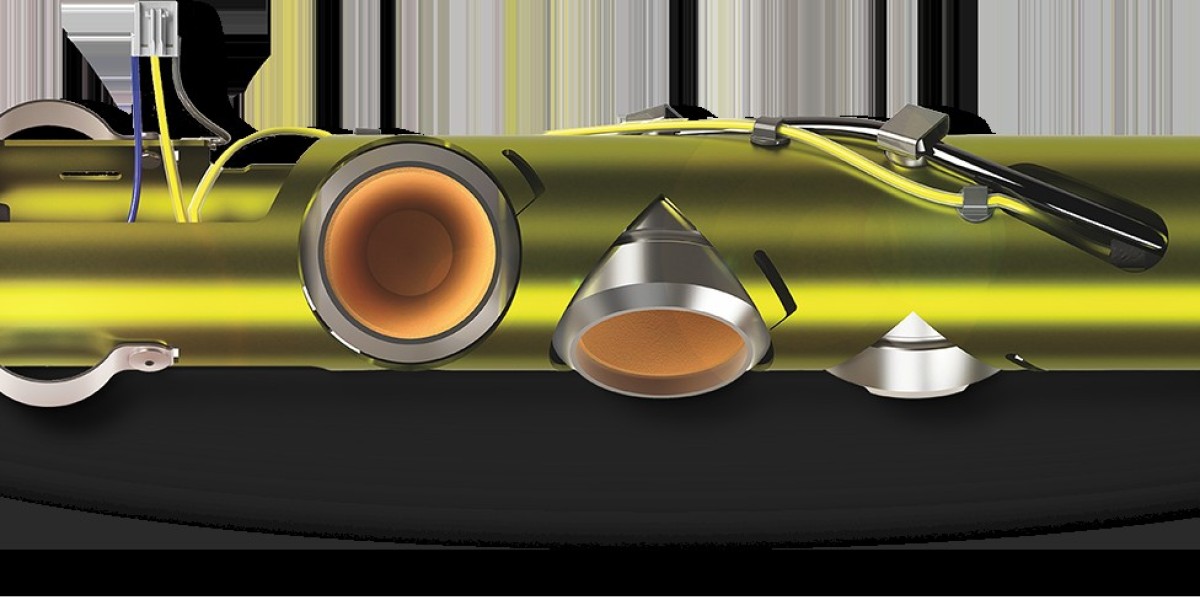

A perforating gun is one of the most critical components in the completion phase of a well. Its primary purpose is to create perforations in the casing or liner, allowing oil and gas to flow into the wellbore.

Key Functions of Perforating Guns

Establish flow paths: Perforating guns create openings in the wellbore for hydrocarbons to enter efficiently.

Precision targeting: Designed to hit specific zones with controlled depth and spacing.

Support fracture stimulation: Ensures optimal fluid placement during hydraulic fracturing.

At G&H Div, our perforating guns are engineered for precision, reliability, and safety. We understand that every well has unique requirements, which is why our solutions are customizable to match operational conditions.

Loaded Perforating Guns: Ready for Action

A loaded perforating gun is a perforating gun pre-assembled with explosive charges. This configuration allows operators to deploy the tool quickly and efficiently, minimizing time and handling risks.

Benefits of Loaded Perforating Guns

Immediate deployment: Saves time in the field and speeds up well completion.

Enhanced safety: Reduces on-site assembly, lowering exposure to explosives.

Reliable performance: Factory-loaded guns are tested for consistent results.

G&H Div’s loaded perforating guns are designed to deliver consistent, predictable perforations, ensuring optimal production outcomes while maintaining high safety standards.

Frac Plug Setting Tools: Ensuring Accurate Placement

A frac plug setting tool is an essential device used to install frac plugs in precise locations within the wellbore. Proper placement is critical for zonal isolation and efficient hydraulic fracturing operations.

Advantages of Using Frac Plug Setting Tools

Accurate positioning: Ensures frac plugs are set exactly where needed for maximum effectiveness.

Time efficiency: Reduces operational delays by streamlining installation.

Enhanced safety: Minimizes the need for repeated interventions in the well.

At G&H Div, our frac plug setting tools are designed for ease of use, precision, and durability. We help operators achieve reliable well isolation, improving both safety and production efficiency.

How G&H Div Supports Operators

At G&H Div, we do more than supply tools—we provide solutions that help operators maximize well productivity and minimize risk.

Why Choose G&H Div

Technical expertise: Our team guides operators on selecting the right tools for their well conditions.

Custom solutions: Equipment can be tailored to match pressure, temperature, and completion requirements.

Reliability and safety: Every tool is rigorously tested for performance in challenging environments.

Ongoing support: From initial consultation to field deployment, we offer expert guidance at every stage.

By combining advanced technologies like perforating guns, loaded perforating guns, and frac plug setting tools, G&H Div ensures operators can perform well completions efficiently and safely.

Best Practices for Using These Tools

To maximize the effectiveness of perforating and fracturing operations, operators should adopt the following best practices:

Plan ahead: Analyze well conditions and determine the best tool for each zone.

Monitor performance: Use real-time data to ensure perforations and plugs function as intended.

Maintain equipment: Regular inspection and maintenance of tools prevent failures.

Train personnel: Ensure field teams are proficient in safe handling and deployment procedures.

Following these best practices helps operators reduce downtime, enhance safety, and achieve optimal production results.

Integrating Technology for Greater Efficiency

The combination of perforating guns, loaded perforating guns, and frac plug setting tools represents a modern approach to well completion. By integrating these technologies, operators can:

Reduce operational complexity and field time

Increase safety through precise and reliable deployment

Improve hydrocarbon recovery by targeting the correct zones

Minimize costs associated with delays, rework, or equipment failure

At G&H Div, we focus on providing tools and solutions that are not only high-performing but also easy to integrate into your existing well operations.

Conclusion

Well completion is a complex process that requires precision, reliability, and expertise. Perforating guns, loaded perforating guns, and frac plug setting tools are essential instruments that make these operations efficient, safe, and productive.

At G&H Div, we combine innovative technology, rigorous testing, and unmatched expertise to deliver tools that meet the demanding needs of the oil and gas industry. Whether you’re deploying a perforating gun, setting a frac plug, or using a loaded perforating gun, our solutions are designed to maximize efficiency and minimize risk.