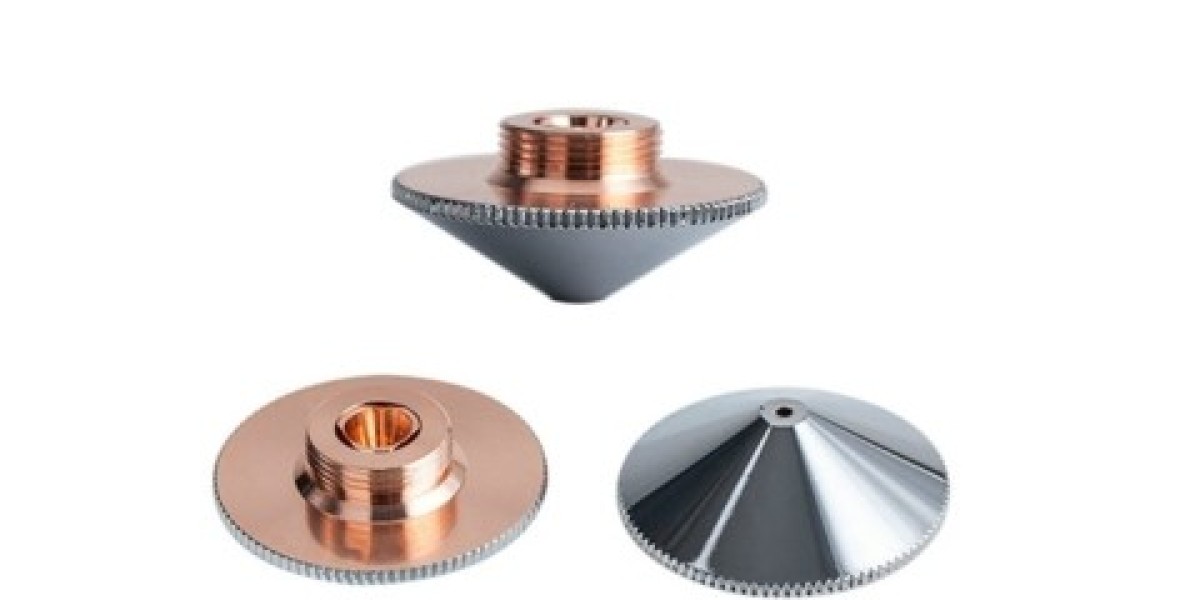

LaserChina offers top-of-the-line solutions for industrial laser cutting with a focus on efficiency, precision, and durability. Among the most critical components in any laser cutting system is the Laser Nozzle, which plays a vital role in directing the laser beam accurately onto materials. Choosing the right nozzle ensures higher cutting quality, smoother edges, and consistent performance. At LaserChina, each nozzle is engineered for superior airflow, stability, and long-lasting operation, making it a trusted choice for professionals across industries.

Precision Engineering for Exceptional Performance

The Laser Nozzle from LaserChina is designed to deliver optimal precision in cutting and engraving applications. Its construction ensures that the laser beam is concentrated exactly where it is needed, resulting in cleaner cuts and reduced material wastage. Advanced manufacturing techniques allow LaserChina nozzles to maintain high consistency in beam alignment and flow, enhancing efficiency in repetitive industrial operations. With precise engineering, users can achieve intricate designs and complex shapes without compromising speed or accuracy.

Advantages of Using LaserChina Nozzles

LaserChina’s Laser Nozzle offers a range of advantages for professionals in manufacturing, automotive, aerospace, and other sectors. Key benefits include:

Enhanced Cutting Quality: Smooth and accurate cuts every time with minimal rough edges.

High Durability: Crafted from premium materials to withstand high temperatures and extended use.

Consistent Performance: Maintains beam focus and airflow for reliable results in every project.

Energy Efficiency: Optimized design reduces power consumption while delivering maximum output.

These advantages make LaserChina nozzles a preferred choice for companies looking to maximize productivity and reduce operational costs.

Wide Range of Applications

LaserChina’s Laser Nozzle is suitable for a variety of laser systems, including fiber lasers, CO2 lasers, and hybrid laser setups. Industries that benefit from these nozzles include metal fabrication, signage production, automotive components, and electronic manufacturing. By ensuring precise laser direction, LaserChina nozzles allow businesses to cut metals, plastics, and other materials with exceptional accuracy and speed. Their versatility makes them an essential component in both small-scale workshops and large industrial operations.

Quality Assurance and Reliability

Every Laser Nozzle at LaserChina undergoes strict quality control to guarantee performance and longevity. Rigorous testing ensures that each nozzle meets the highest standards for airflow, laser focus, and material resistance. Customers can rely on LaserChina for consistent delivery of nozzles that maintain superior cutting performance over time. This commitment to quality reassures businesses that their laser cutting processes will remain efficient, accurate, and dependable.

Benefits for Industrial Efficiency

Using LaserChina’s Laser Nozzle translates directly into operational efficiency. Faster cutting speeds, fewer defects, and reduced downtime are among the immediate benefits. The precise airflow control also minimizes the need for secondary finishing, saving time and labor. By investing in high-quality nozzles from LaserChina, companies experience smoother workflows, enhanced productivity, and more consistent output, which ultimately boosts profitability and competitive advantage in the market.

Final Thoughts

LaserChina’s Laser Nozzle is more than just a component; it is a vital tool that ensures every laser cutting project reaches its highest potential. With unmatched precision, durability, and efficiency, these nozzles enhance cutting quality while reducing waste and operational costs. Whether for industrial manufacturing or specialized fabrication, LaserChina delivers reliable solutions that support excellence, productivity, and long-term performance. Choosing LaserChina means choosing precision, reliability, and innovation in every laser cutting application.